(资料来源:成果报道、食品放大镜)

近日,中国海洋大学食品学院Yanchi Wu(第一作者),郑洪伟副教授(通讯作者)、薛长湖院士(通讯作者)等在国际食品顶刊《Food Hydrocolloids》(中科院一区,IF:11.0)发表了题为“Construction of 3D printed salmon fillet simulants: Improving printing performance by blending corn starch and flaxseed oil with pea protein and post-printing texturization via transglutaminase”的研究论文。

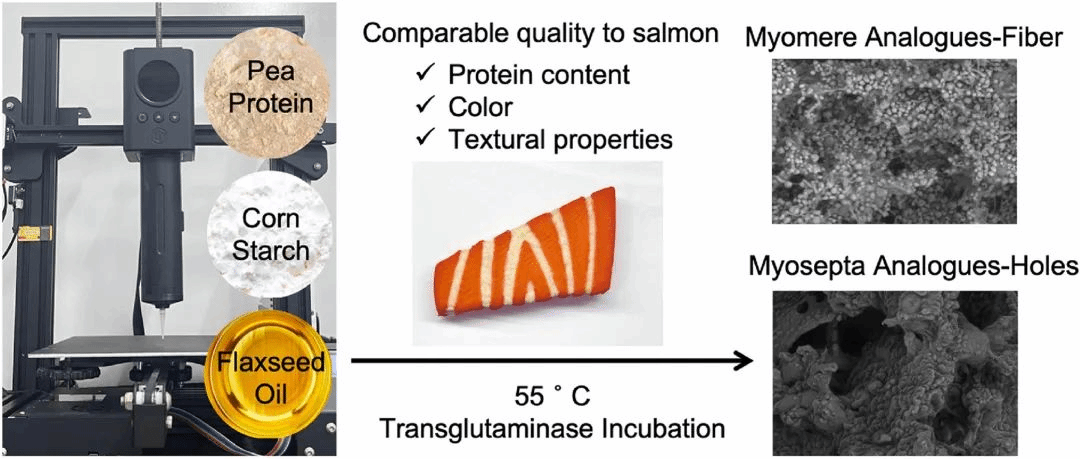

植物基鱼类似物已经被提出作为应对传统水产不足和环境挑战的一种可持续解决方案。在该研究中,研究人员利用3D打印技术结合谷氨酰胺转胺酶 (TGase)后处理来构建结构稳定的仿三文鱼片。3D打印策略已经被证实在精确模拟天然鱼结构上的潜力。而TGase能够调节生物墨水的结构和质地,最终影响仿鱼的特征。与高温螺旋挤压和静电纺丝技术相比,在3D打印中通过TGase催化蛋白质聚集形成的纤维可能更短,从而导致在质地上更接近天然鱼片。

含有玉米淀粉(CS)、亚麻籽油(FO)和豌豆蛋白(PP)的肌节生物墨水被优化来构建结构稳定的类似物。根据真实三文鱼片的常量营养素,研究人员将亚麻籽油和豌豆蛋白肌膈生物墨水注射到3D打印肌节类似物中。研究人员系统表征了肌节和肌膈生物墨水的流变性、肌节和肌膈类似物的微结构和化学组成。研究人员将TGase加入到肌节和肌膈模拟物中来实现糊状物-固体转变。打印的原仿三文鱼片被微波处理来获得烹饪仿三文鱼。研究人员探究了原和烹饪仿三文鱼片的质构。制备的仿三文鱼片在肌节类似物中具有像鱼肉的纤维结构,在质构上与真实三文鱼片具有很好的相似性,这证实了在模拟更好鱼肉质构上的巨大潜力。

图形摘要

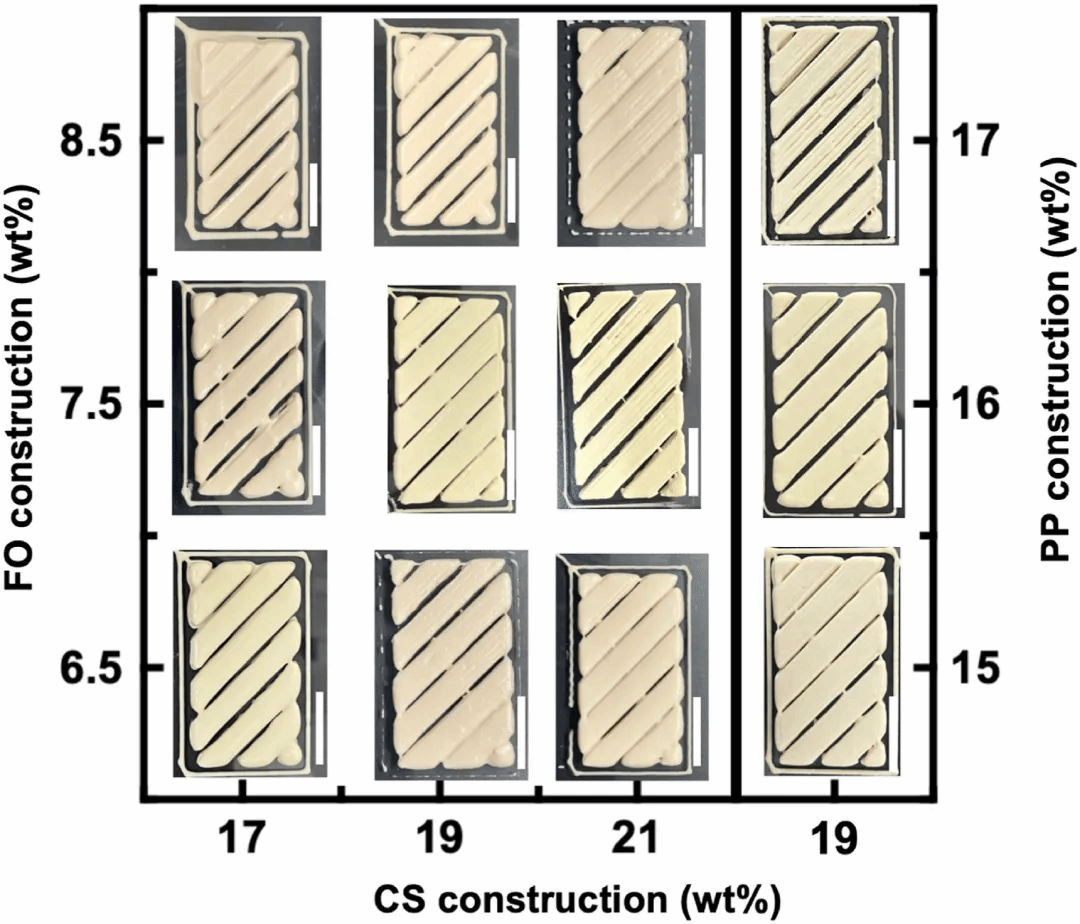

Fig. 1. Stable myomere simulants at different CS (17–21 wt% of corn starch), FO (6.5–8.5 wt% of flaxseed oil), and PP (15–17 wt% of pea protein) contents for 3D printing test. The printed model is a rectangle (width, 30 mm; length, 57 mm; height, 3 mm) with stripes (width, 2 mm) inside. The white scale bars are 20 mm.

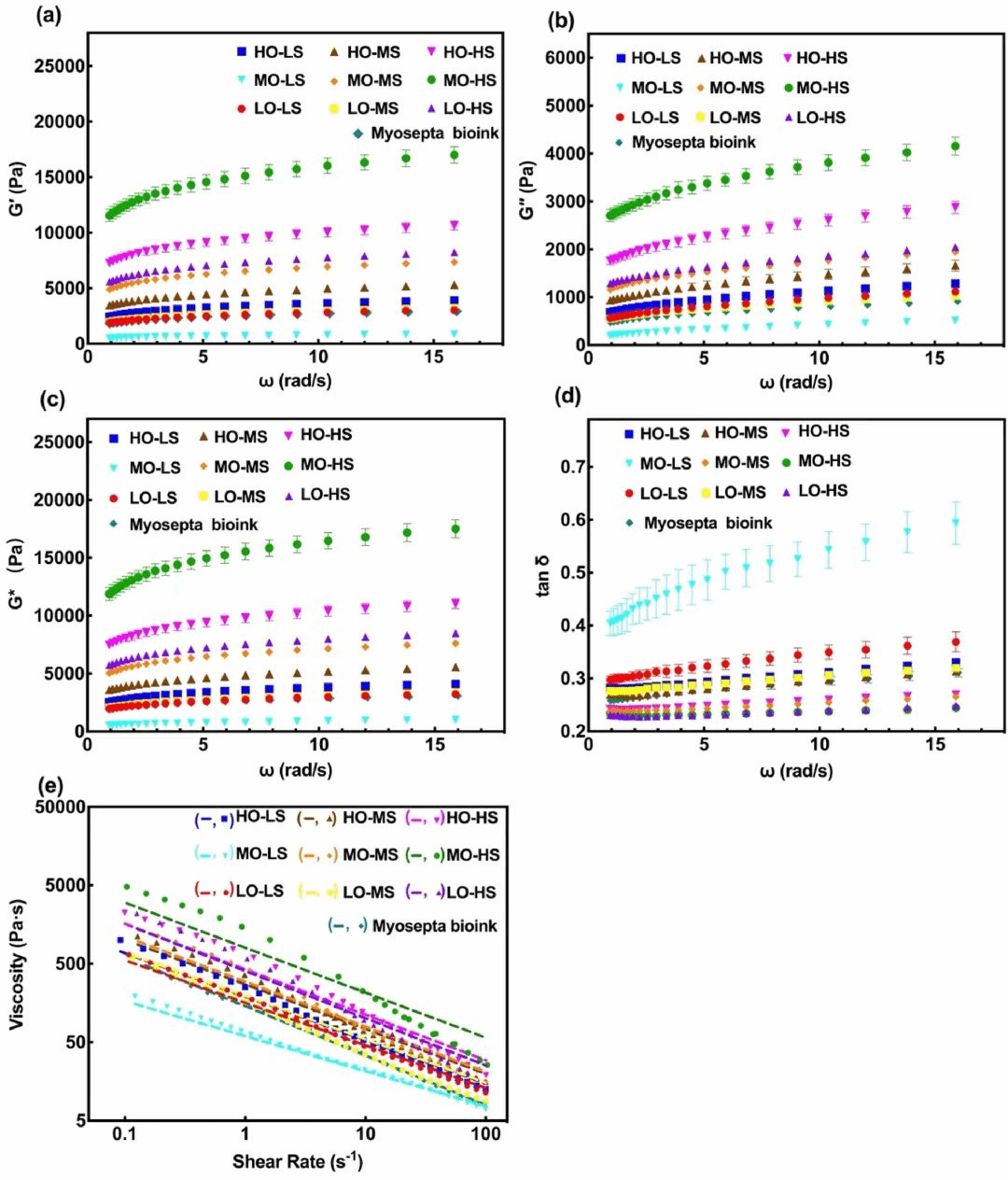

Fig. 2. Rheological behavior of bioinks. (a) Storage modulus G′, (b) loss modulus G″, (c) complex modulus G*, and (d) loss tangent (tan δ = G″/G′) of the stable myomere and myosepta simulants bioinks. (e) Shear-thinning behaviors of stable myomere and myosepta simulants. Ostwald de Waele fitted lines were dotted by straight line segments and raw data was dotted by solid points. Pea protein (PP) content was 16 wt%. Lower oil content of 6.5 wt% was denoted as LO. Medium oil content of 7.5 wt% was denoted as MO. Higher oil content of 8.5 wt% was denoted as HO. Lower starch content of 17 wt% was denoted as LS. Medium starch content of 19 wt% was denoted as MS. Higher starch content of 21 wt% was denoted as HS.

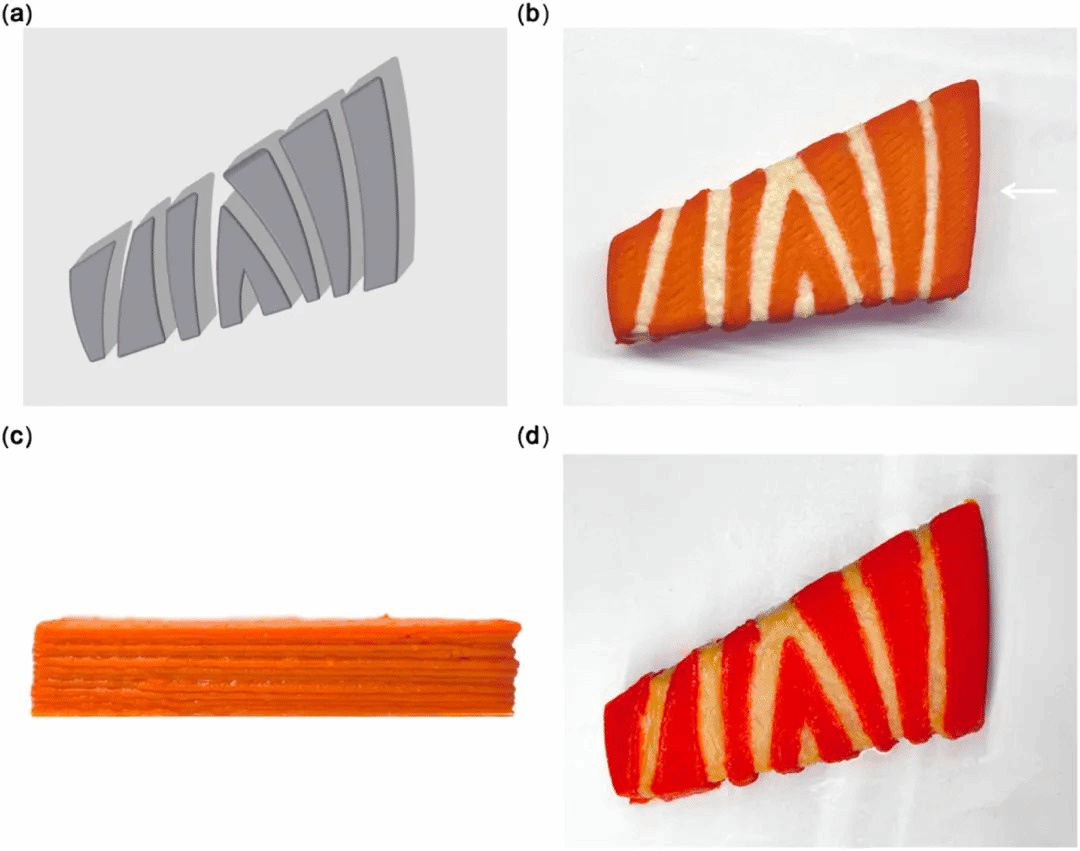

Fig. 3. 3D model of myomere analogues from the top view (a) and images of 3D printed raw salmon fillet simulant from the top (b) and the side (c) views, and cooked salmon fillet simulant from the top view (d). The white arrow (→) indicates the shooting angle of the side view (c). Red parts are myomere analogues printed by 3D printer and white myosepta bioinks were injected between the printed myomere analogues.

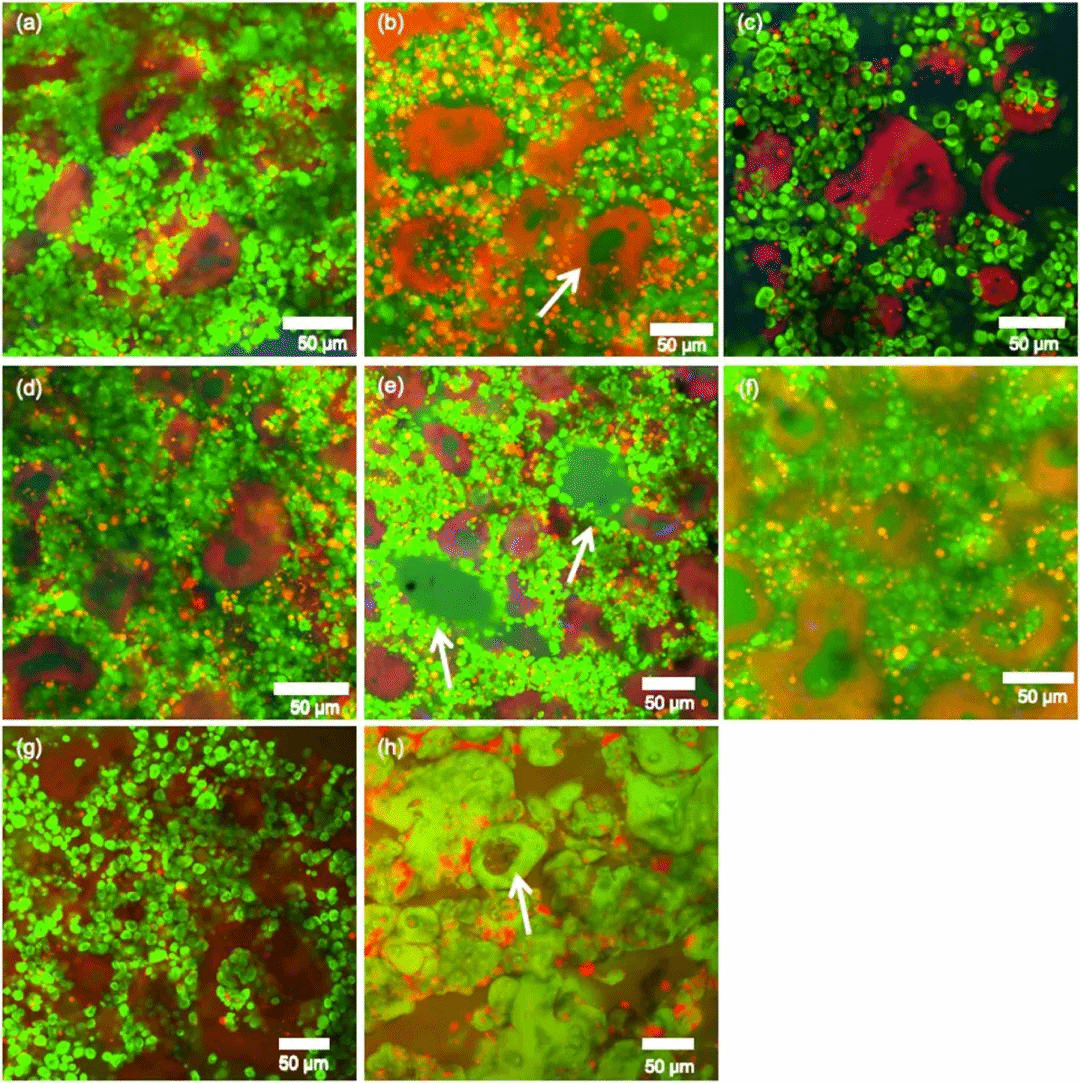

Fig. 4. CLSM images of myomere and myosepta analogues at different incubation times. (a–f) Myomere analogues after 0 h, 2 h, 4 h, 6 h, 8 h, and 10 h incubation, and (h) myosepta analogues interface after 10 h incubation with TGase at 40× magnifications. (g) Myomere analogue without TGase after 10 h incubation at 40× magnifications. The white arrow (→) indicates the holes produced. The white scale bars are 50 μm. Green represents the protein labeled by FITC and Nile blue, red represents the oil labeled by Nile red, and blue represents the starch polysaccharide labeled by Calcofluor White.

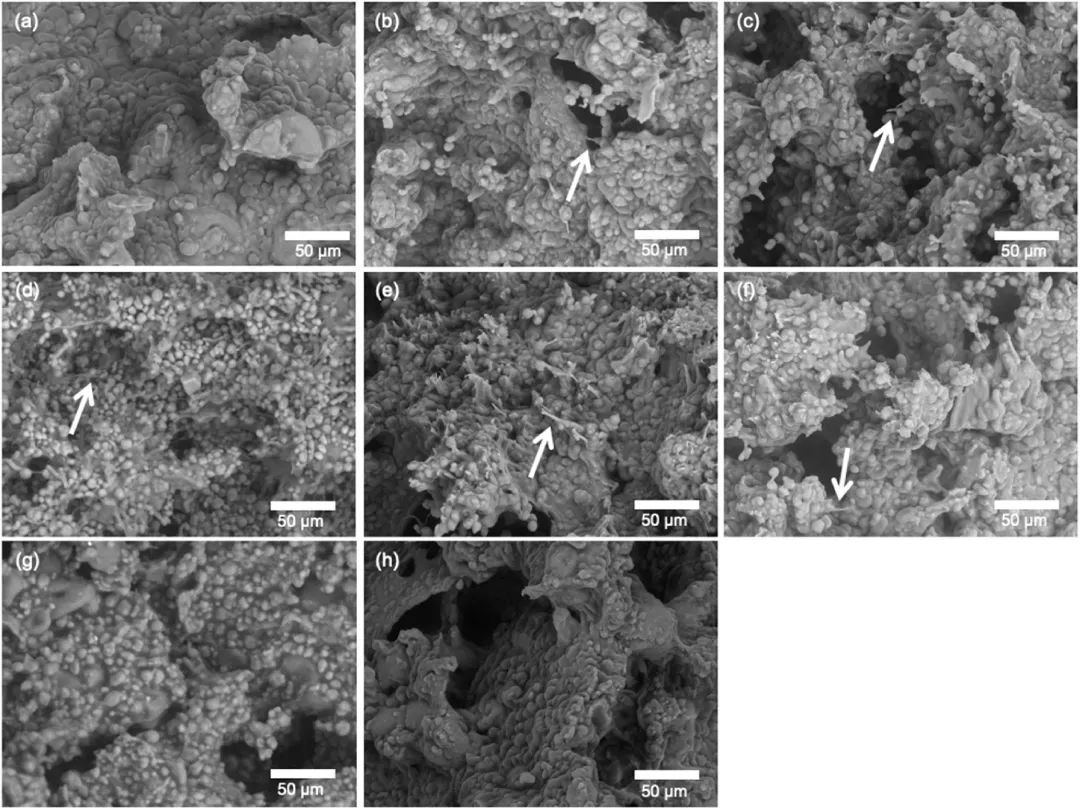

Fig. 5. SEM images of myomere and myosepta analogues at different incubation times. (a–f) Myomere analogues after 0 h, 2 h, 4 h, 6 h, 8 h, and 10 h incubation, and (h) myosepta analogue interface after 10 h incubation with TGase at 1000× magnifications. (g) Myomere analogue without TGase after 10 h incubation at 1000× magnifications. The white arrow (→) indicates the fibre produced. The white scale bars are 50 μm.

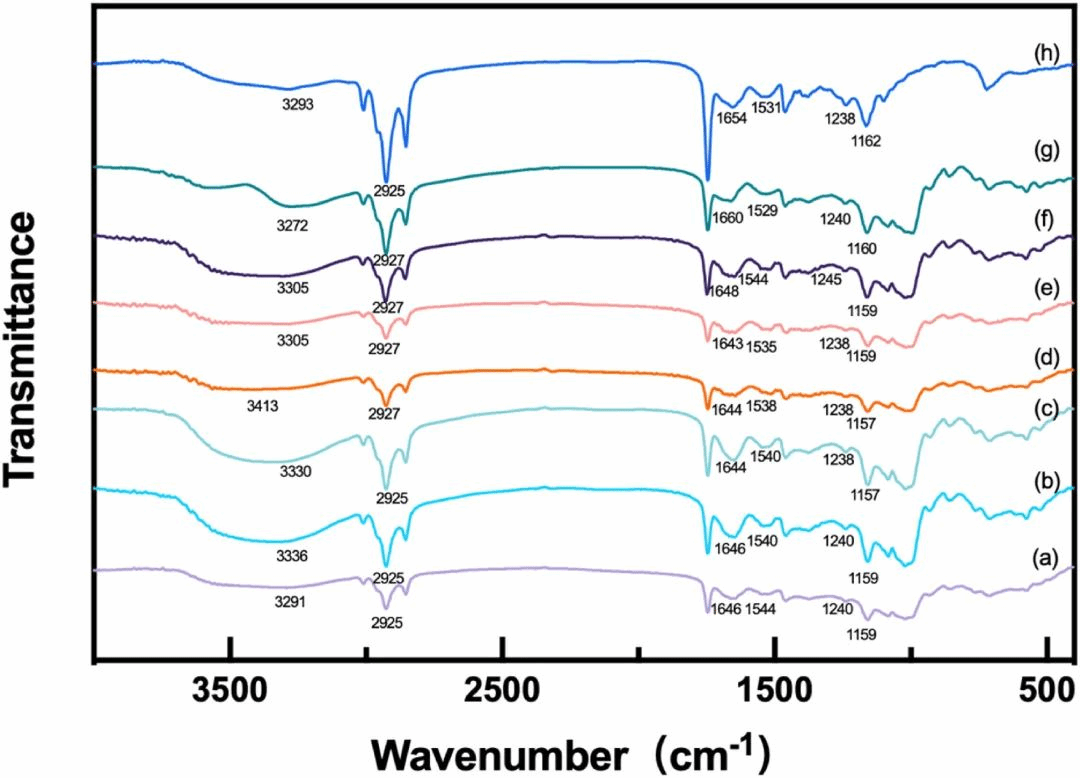

Fig. 6. FT-IR spectra analysis of myomere and myosepta analogues at different incubation times. (a–f) Myomere analogues after 0 h, 2 h, 4 h, 6 h, 8 h, and 10 h incubation, and (h) myosepta analogue interface after 10 h incubation with TGase. (g) Myomere analogue without TGase after 10 h incubation.

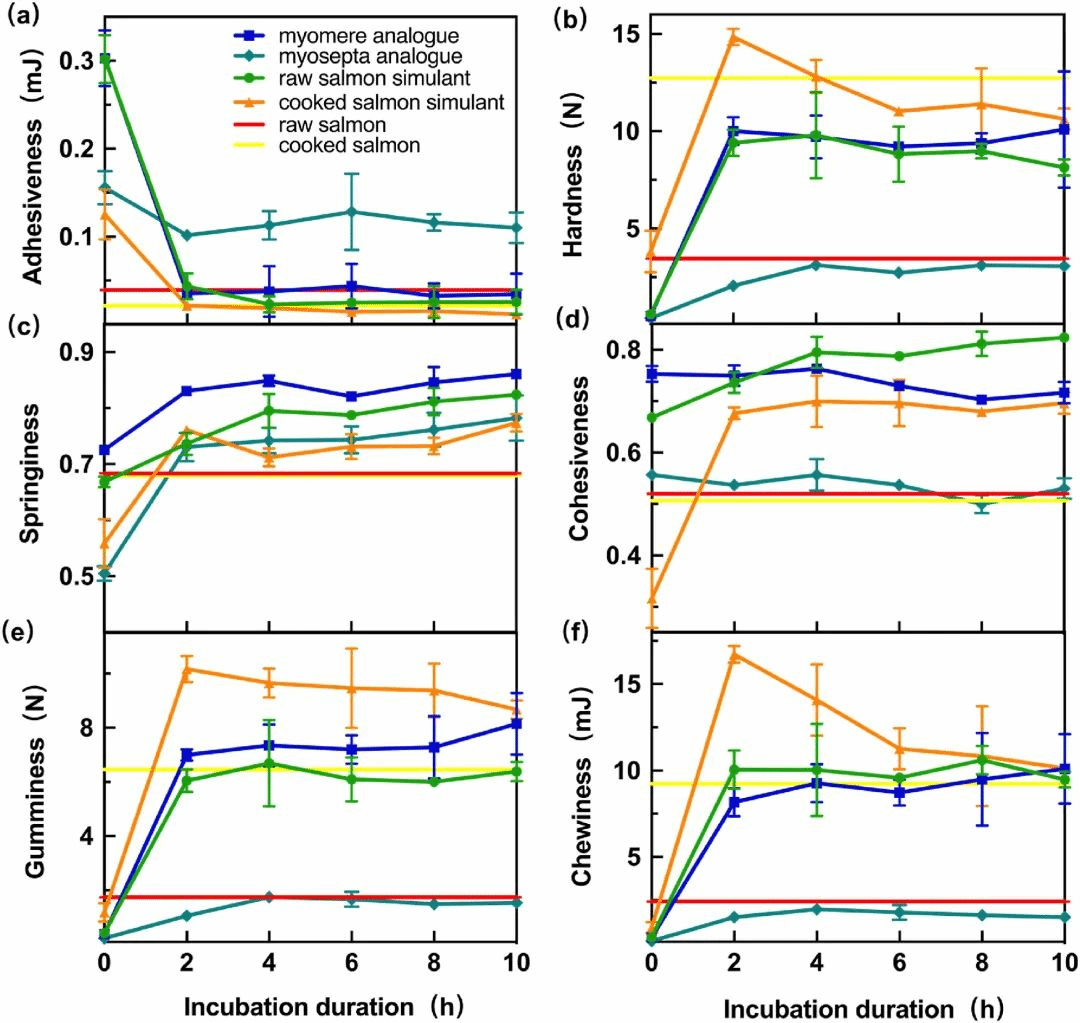

Fig. 7. Effect of incubation time on textural parameters of myomere and myosepta analogues, when they were molded and assembled as raw and cooked printed salmon fillet simulants, relative to real raw and cooked salmon fillets. (a) Adhesiveness, (b) hardness, (c) springiness, (d) cohesiveness, (e) gumminess, and (f) chewiness.

作者简介

薛长湖,中国工程院院士,中国海洋大学教授,山东省食品科学技术学会理事长。入选国家百千万人才工程,教育部新世纪优秀人才支持计划,教育部“长江学者和创新团队发展计划”创新团队负责人,全国首批黄大年式教师团队核心成员,泰山学者攀登计划特聘专家。创新水产品加工专用酶高通量挖掘、理性设计与工程化制备,研发出水产品加工的生化工程技术,建立了以水产加工专用酶为核心的生物加工技术体系。突破水产品高质化干燥技术,发明了水产品固态微波源快速杀菌和鱼糜制品高质化加工技术,实现了水产品的高质化加工利用。阐明了ω-3高不饱和脂肪酸水产特征脂质、海洋硫酸多糖等水产特征功效成分的结构与功能,突破分子蒸馏、定向酶解等功效成分制备核心技术,推动水产加工的营养健康化转型。成果在近百家水产品加工龙头企业转化,新增产值超500亿元;建成甲壳素生物加工、海参高品质加工、海洋活性脂质等生产线几十条,开发出系列高值化产品,广泛应用于食品、农业、材料和生物医药等领域。作为我国水产品加工与贮藏学科带头人,为构建现代水产品加工理论与技术体系、服务渔业高质量发展做出了重要贡献。

郑洪伟,博士、副教授、硕导。瑞典隆德大学(Lund University)联合培养博士,中国海洋大学药学博士后,入选中国海洋大学“青年英才工程”。主持国家级(子)课题3项,以第一或通讯作者发表SCI论文20余篇;申请国家发明专利20余项。主要研究方向为细胞培养鱼肉新理论新技术、海洋生物介质功能调控与生物利用等。

免责申明:我们在分享的同时,十分尊重原创,版权归原创作者所有,如有侵权请联系我们,我们将及时删除